We have designed two parallel sewage pipelines for the discharge of the increased quantities of wastewater, which will transport the generated wastewater directly to the existing wastewater treatment plant.

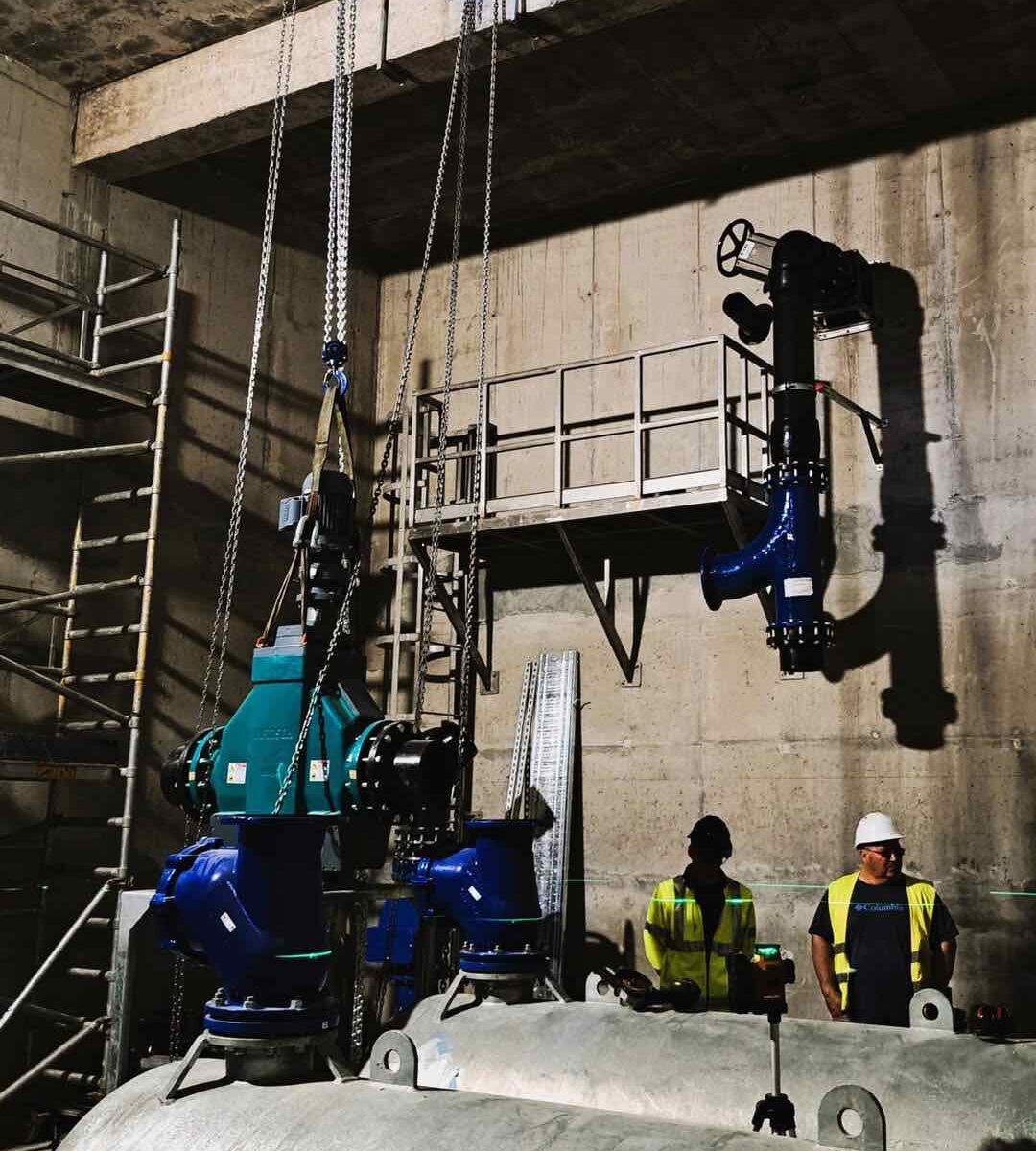

The planned wastewater pumping station has a mixed technology, pneumatic and hydraulic system. The system is primarily pneumatically operated, which avoids the rotting of wastewater. The hydraulic system is only activated during the maintenance of the pneumatic system and in the event of an emergency.

The wastewater currently operating at the hydraulic pumping station in the area of the Makó City Industrial Estate will be transferred to the newly built mixed-system pumping station, so a new stone clay gravity pipeline must be built.

The refurbishment of the SBR facility with a volume of 2,160 m3 at the Makó wastewater treatment plant is necessary for the disposal of the increasing amount of wastewater.

Following the development, the total biological system load is 8,750 m3 per day. This means a sewage load of 1,750 m3/day with our SBR basin (5 units will be in operation).

Planned new facilities summary quantities:

- D225 PE100 SDR17 sewage discharge line: 8,942.2 m

- D180 PE100 SDR17 sewage discharge line: 8,939.9 m

- Gravity jumper DN 400 stoneware: 34.5 m

- Combined pneumatic lifting structure 1 unit: 2,250 m3/day, (approximately 160 m3/hour)

The renovation of the SBR structure:

- Complete replacement of existing mechanical units

- Replacement of air supply elements along with the complete air distribution duct system.

- Replacement of the instruments of the structure (NO3-N; NH4-N ISE online devices, LDO probe with 4-channel SC 1000 signal processor)

- Renovation of the lock structure of the existing transfer case

- Installation of a new blower of 2,880 lm3/h with a capacity of 550 mbar: 2 pcs

- Renovation of the 0.4 kV electric fields of the air blowers belonging to SBR reactors No. 1-3

- Renovation of the 0.4 KV supply fields of the plant.